The Anatomy of Excellence: Deconstructing the 5 Pillars of UltraSlim

Why true minimalism requires maximum engineering.

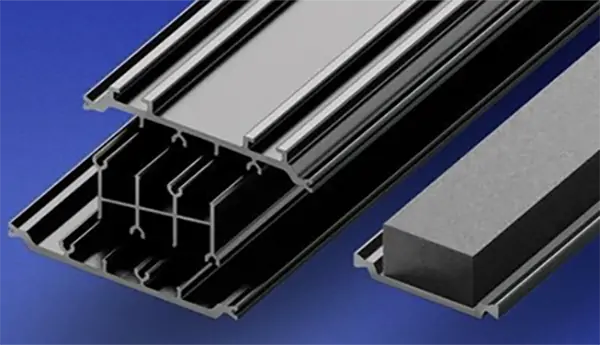

A minimalist window is a deception. To the eye, it appears simple—a single sheet of glass held by a whisper of metal. But as the visible frame shrinks, the engineering burden grows exponentially.

How do you make a 20mm frame support 800kg of glass? How do you ensure a system remains air-tight after 20 years of coastal storms?

At UltraSlim, we do not view ourselves merely as assemblers. We are an engineering atelier. Drawing on thirty years of manufacturing expertise, we have isolated the Five Essential Pillars that separate a standard window from a structural instrument.

Here is the invisible science behind the view.

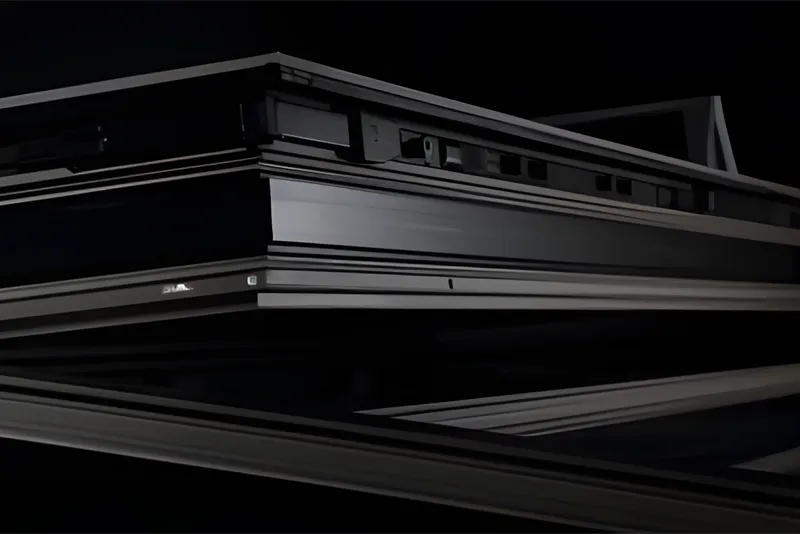

1. The Profile | The Porcelain Armor

The aluminum profile is the skeleton of the system, but its strength is meaningless without longevity.

While others use standard powder coating, we utilize a patented Porcelain Electrophoresis process fortified with fluorocarbon resin. This creates a refined matte finish that not only blocks light pollution but actively performs self-cleaning operations.

- Corrosion Proof: Tested for over 60 hours in extreme CASS (Copper-Accelerated Acetic Acid Salt Spray) conditions.

- The Result: A service life extending beyond 20 years, even in harsh coastal environments.

- The Core: Inside, we use German-imported PA66 + 25% Glass Fiber thermal breaks , creating a world-patented reinforced structure that severs heat transfer while maintaining ironclad rigidity.

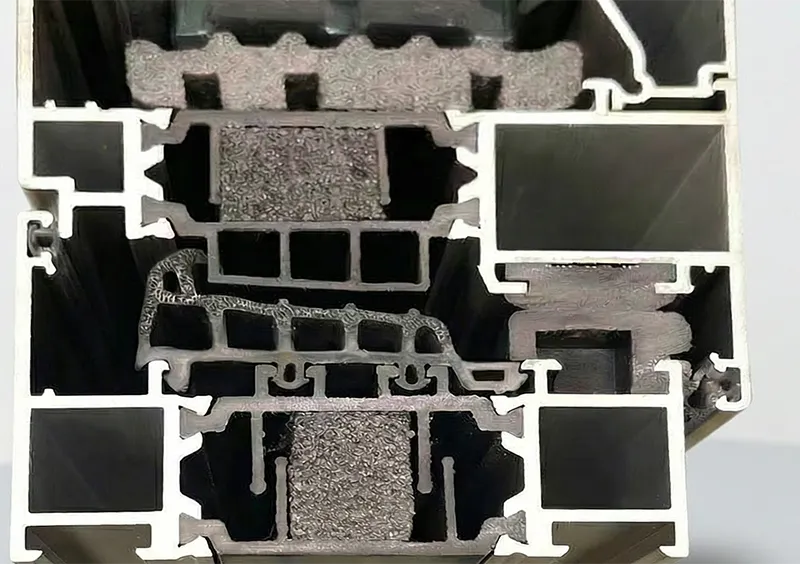

2. The Accessories | The Invisible Weld

A window usually fails at the corners. To prevent this, we rejected standard mechanical joining. We utilize a Fused Corner Process, where high-strength aluminum keys are injected with structural glue. This merges the frame corners into a single, absolute solid unit.

- Micro-Precision: Specialized locating pins maintain exact alignment between components.

- The Result: A frame that never experiences deformation or sagging, regardless of decades of heavy use.

3. The Hardware | The Hidden Muscle

Luxury is defined by the sensation of movement. A heavy sash must feel weightless. We utilize authentic imported hardware designed to handle massive loads while remaining completely concealed.

- Serious Capacity: Our systems support up to 170kg for windows and 180kg for doors, enabling architects to design massive, uninterrupted glass spans.

- Relentless Testing: Every system undergoes punishing cycle testing—over 100,000 cycles for windows and 200,000 for doors. The failure rate? Zero.

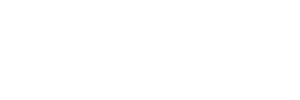

4. The Sealant | Aviation-Grade Sealing

A window is only as good as its seal. If air gets in, the illusion is broken. We abandoned standard rubber for Aviation-Grade EPDM gaskets. Using a co-extruded foam structure with soft and hard elements, we created a "honeycomb" interior.

- The Physics: This honeycomb structure allows for better compression and reduced resistance.

- The Result: An exceptional barrier against water, air, and sound that far surpasses standard rubber seals.

5. The Glass | The Suspended Film Game-Changer

The defining element of any window is its transparency.

Standard triple glazing solves insulation but creates new problems: it is heavy, bulky, and prone to optical distortion. We introduced Suspended Film Technology to solve this contradiction. By suspending a specialized anti-UV film between two panes of Low-E glass, we create multiple insulation chambers without the massive weight of a third glass pane.

- Perfect Optics: Our production process includes double-chamber forced convection heating and low-temperature tempering.

- The Result: We achieve perfect flatness, eliminating the "wavy" visual distortions common in standard tempered glass and ensuring your view remains optically true.

The Integrity of Integration

Why does "Factory Direct" matter?

Because a window is a unified system, not just a collection of parts. Distributors often purchase components separately without verifying their compatibility.

At UltraSlim, we engineer the relationships between the components. We understand exactly how the Honeycomb EPDM interacts with the Porcelain Electrophoresis surface to prevent seal degradation. We calculate how the lightweight nature of the Suspended Film reduces stress on the Imported Hardware, ensuring the hinges operate smoothly for decades.

A true luxury experience emerges from this integration. It is the result of twenty years of testing, strictly controlled in our own facility, to achieve one singular goal: Complete System Excellence.

- Previous: None

- Next: The Architecture of Survival: From the South Pole to Your Sanctuary